It's been some time since I posted anything on these forums. Heck, it's been sometime since anybody has posted. Anyway, after reading Mechie's post, I figured I might as well jump in. Maybe revive these forums :)

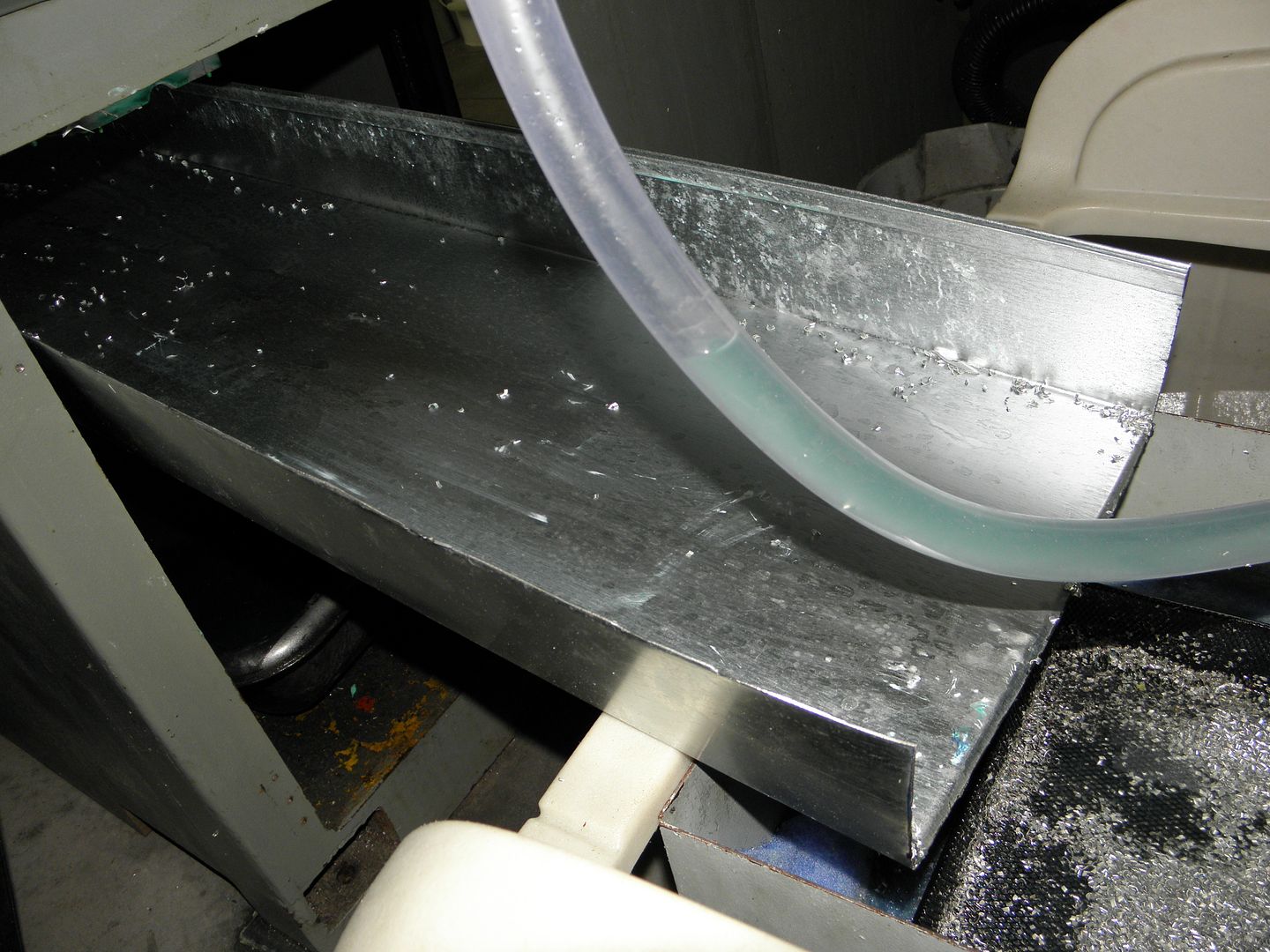

I made a few changes to the mill and more are coming. One of the changes was the cooling system....it had to go. I was sick and tired of the tiny little drain getting clogged up and the pan filling with coolant. So I drilled a 4 inch drain hole on the opposite side of the original drain. I also upgraded the coolant pump and tank.

Here are some pics...

![]()

![]()

I re-purposed my grand kids toy box :) Right now , it has 20 gallons in it. I think I can do 25 :) I was originally using 2" pvc for the drain, but found that it didn't drain good enough...chips were collecting and such. So i bought some heating duct and made up what you see in the picture. This works well and I'll probably make up another tray using 18 gauge steel. The pump is a submersible utility pump from Harbor Freight and it works great...plenty of pressure. As you can see, I also re-used the mikini coolant setup. It's now my filtering system.

I don't have a picture of it, but after cutting the hole and removing the old drain setup. I epoxied in two pieces of 4" diameter, about 2" long tubing (one for each drain). Without this, the coolant would travel through molecular adhesion, beyond the tray area and you'll get coolant everywhere....Oh and thanks to the coolant issue, I also removed the power supply from under the mill and installed it in its own enclosure, mounted on the rear wall of the mill.

I also installed new plumbing for the coolant..using 1/2" pvc. Where the original setup came up from the drain area, it now comes in through the rear.

![]()

I also installed a wash down hose....

![]()

So much better than blasting chips with air.

I had some neoprene laying around and figured I put it to some good use....

![]()

So what's up for the near future... I mentioned it in mechie's post. I'll be installing these.....

![]()

They are... a 1200 oz.in and two 940 oz.in steppers. I been having some issues with the Z loosing steps and instead of chasing my tail looking for the reason, I'll just install all new steppers and digital drivers.

Lastly, I have some choices for the spindle motor. I have a 4 pole motor setup, very similar to Allen's setup. I also have a Kollmorgen 3KW servo, it has a resolver attached to it and I found a driver for it that may work. But, this servo stuff is kind of a new to me and I don't want to have the mill in limbo learning this stuff.......I also have this bad boy... A FLENDER HIMMEL 3KW (4hp) AC motor.

![]()

The beauty about this thing is that it has a 4 1/2" mounting base.. The frame is aluminum, but the front bracket is cast iron. Total weight is about 40 lbs.

![]()

When i got it home, I took it apart to make sure things were ok and found that the fan was missing. I was kinda of upset, but, I figured I can come up with a solution and here it is....

![]()

I had a couple 220 volt case fans taking up space and put them to use..... I gutted out one fan to act as a spacer to clear the shaft.

I hooked the motor up to a vfd and gave it a test run. It ran great at 4000 rpm, so i took it to 6000 rpm, then to 8000 rpm, I went to 10,000 rpm and it purred like a kitten. I chickened out going further, but, it sounded like it could take more.

I'm really leaning towards this motor as all my machining is with aluminum. I've also been looking at maybe a second mill and it won't be a Mikini .....

That's it for the updates... and sorry for the long post ...was kinda bored and hopefully we can revive these forums :)

I made a few changes to the mill and more are coming. One of the changes was the cooling system....it had to go. I was sick and tired of the tiny little drain getting clogged up and the pan filling with coolant. So I drilled a 4 inch drain hole on the opposite side of the original drain. I also upgraded the coolant pump and tank.

Here are some pics...

I re-purposed my grand kids toy box :) Right now , it has 20 gallons in it. I think I can do 25 :) I was originally using 2" pvc for the drain, but found that it didn't drain good enough...chips were collecting and such. So i bought some heating duct and made up what you see in the picture. This works well and I'll probably make up another tray using 18 gauge steel. The pump is a submersible utility pump from Harbor Freight and it works great...plenty of pressure. As you can see, I also re-used the mikini coolant setup. It's now my filtering system.

I don't have a picture of it, but after cutting the hole and removing the old drain setup. I epoxied in two pieces of 4" diameter, about 2" long tubing (one for each drain). Without this, the coolant would travel through molecular adhesion, beyond the tray area and you'll get coolant everywhere....Oh and thanks to the coolant issue, I also removed the power supply from under the mill and installed it in its own enclosure, mounted on the rear wall of the mill.

I also installed new plumbing for the coolant..using 1/2" pvc. Where the original setup came up from the drain area, it now comes in through the rear.

I also installed a wash down hose....

So much better than blasting chips with air.

I had some neoprene laying around and figured I put it to some good use....

So what's up for the near future... I mentioned it in mechie's post. I'll be installing these.....

They are... a 1200 oz.in and two 940 oz.in steppers. I been having some issues with the Z loosing steps and instead of chasing my tail looking for the reason, I'll just install all new steppers and digital drivers.

Lastly, I have some choices for the spindle motor. I have a 4 pole motor setup, very similar to Allen's setup. I also have a Kollmorgen 3KW servo, it has a resolver attached to it and I found a driver for it that may work. But, this servo stuff is kind of a new to me and I don't want to have the mill in limbo learning this stuff.......I also have this bad boy... A FLENDER HIMMEL 3KW (4hp) AC motor.

The beauty about this thing is that it has a 4 1/2" mounting base.. The frame is aluminum, but the front bracket is cast iron. Total weight is about 40 lbs.

When i got it home, I took it apart to make sure things were ok and found that the fan was missing. I was kinda of upset, but, I figured I can come up with a solution and here it is....

I had a couple 220 volt case fans taking up space and put them to use..... I gutted out one fan to act as a spacer to clear the shaft.

I hooked the motor up to a vfd and gave it a test run. It ran great at 4000 rpm, so i took it to 6000 rpm, then to 8000 rpm, I went to 10,000 rpm and it purred like a kitten. I chickened out going further, but, it sounded like it could take more.

I'm really leaning towards this motor as all my machining is with aluminum. I've also been looking at maybe a second mill and it won't be a Mikini .....

That's it for the updates... and sorry for the long post ...was kinda bored and hopefully we can revive these forums :)